Non-Destructive Testing (NDT) methods, such as visual examination using a boroscope and drones, are widely used in various industries to inspect and evaluate the condition of equipment, structures, and components without causing damage. Here’s a brief overview of how these methods work:

- Visual Examination using Boroscope:

- A borescope is a slender, flexible or rigid optical instrument with a camera and a light source at its tip. It’s designed to access and inspect areas that are difficult to reach.

- Boroscopes are used for visual examination of components like pipes, engines, turbines, and more. They can be inserted into small openings, pipes, or complex machinery.

- The operator views the live or recorded video feed from the boroscope on a monitor. This allows them to assess the condition and identify any defects or anomalies.

- Boroscopes are particularly useful for inspecting the internal condition of equipment and structures, often in the aerospace, automotive, and oil and gas industries.

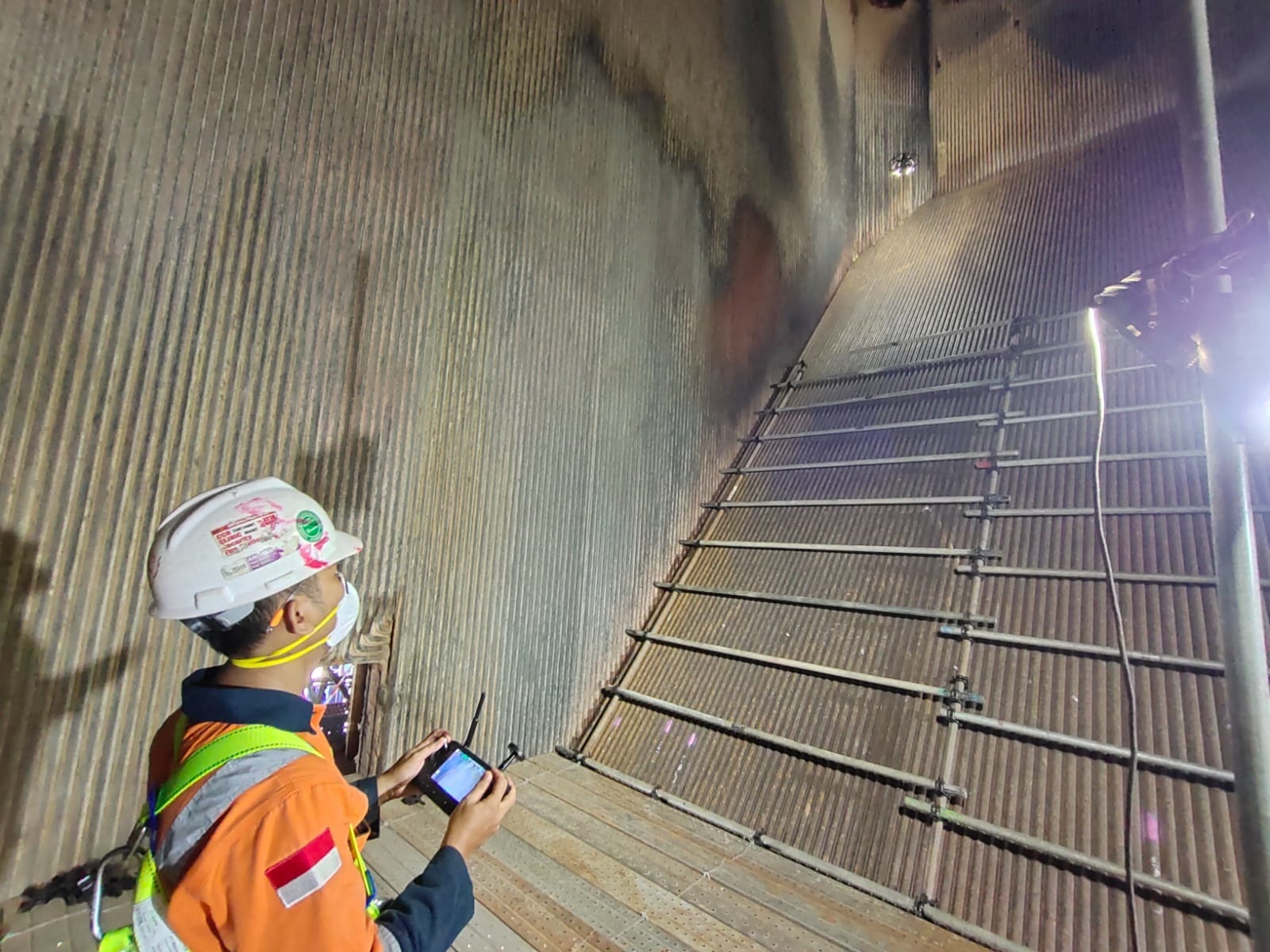

- Drone-Based Visual Inspection (Aerial Inspection):

- Drones, also known as Unmanned Aerial Vehicles (UAVs) or Unmanned Aircraft Systems (UAS), are equipped with cameras and other sensors for visual inspections.

- Drones are used for inspecting large and hard-to-reach structures, such as boiler, chimney, bridges, buildings, wind turbines, power lines, and more.

- The operator controls the drone remotely and uses its camera feed to assess the condition of the structure or component. Drones can capture images and videos from various angles and heights.

- They are especially useful for conducting inspections in hazardous or inaccessible environments, reducing the need for human inspectors to enter these areas.

Both boroscopes and drones offer several advantages in NDT:

- Safety: They reduce the need for human inspectors to enter hazardous or confined spaces.

- Efficiency: They can inspect large areas or complex machinery quickly.

- Cost-Effective: They often reduce inspection costs by minimizing downtime and labor.

- Documentation: They provide visual evidence of the condition, which can be valuable for records and analysis.

- Access: They can reach areas that are otherwise difficult to access.

However, it’s important to note that the effectiveness of these methods depends on the skill of the operator, the quality of the equipment used, and the specific requirements of the inspection. In some cases, other NDT methods like ultrasonic testing, radiography, or magnetic particle inspection may be necessary to complement visual examinations.